|

B. 1200MM

wide web soft Hologram embosser

click link to see running Hologram embosser

or right click mouse to 'save as...' to download it

Vedio1 Vedio2

1200mm width soft Hologram embosser

is designed for producing 1200mm width Hologram

film. It meets the up-date need of Hologram printing

and packaging industries or Hologram gifts and decoration

industries.

This Machine(Hologram Printer) has good preformance to emboss

material such as BOPP, PVC, PET and CPP, extensively

used in manufacturing top grade packing material to

prevent counterfeit.

Performance and Characteristics of soft Hologram

embosser£ň

1. It only requires 20 minutes of heating to achieve

work requirement, automatically coordinating with cooling

system and realizing heat energy balance. Furthermore,

It not only can save energyby two-third, but also work

constantly and stably.

2. Jointing seam will not expand with hot.

Specifications:

1.Width of soft Hologram embosser's roll:

1320mm

2.Width of Press Film: 1250mm

3.Max. Diameter of winding and rewinding: 580mm

4.Coling system: Oil and water cool system

5.Speed of Press Film: 0M-50M/Min.

6.Meter Counte: Automatic meter counter

7.Thickness of Material(Film, BOPP, PET, PVC): 0.012-0.200mm

8.Temperature controlling: temp.0--200C

9.Compressed air needs: 6 ATM

10.Frequency-change speed-change Motor: 2.2KW

11.Auto temperature perseverance system: 12.5KW

12.Total Power consumption: 16 KW

13.Weight of Main Hologram embosser: 1.5T

14.Hologram embosser dimension of Main Machine(Hologram Printer): W1800‘“L1200‘“H1500mm

The

making of a Hologram can be divided into 2 procedures.

The making of a master Hologram and the making of a

reflection Hologram. hey both have to be recorded in

total darkness. The recording of holograms is a process

sensible to vibrations.

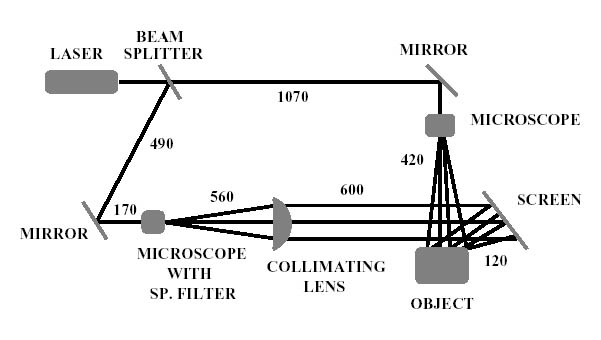

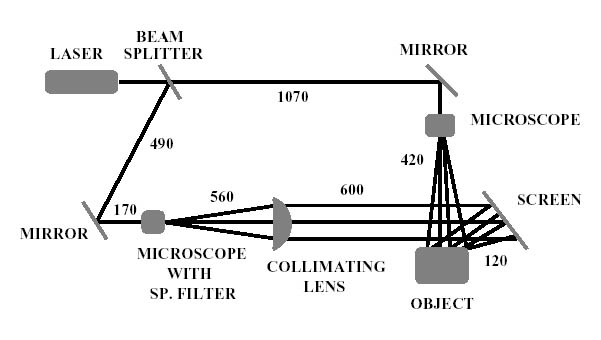

Let's start with the recording of a master Hologram.

(1) To record a master Hologram, a few things are needed:

an object, a Hologram film, a beamsplitter and a

laser. The lenses and mirrors needed to focus and lead

the laserbeams will not be discussed here. The laserbeam

is split into two beams using the beamsplitter.

One beam is sent straight to the Hologram film,

this beam is called the reference beam. The

other beam, the  object

beam, is sent to the object, which is placed in front

of the Hologram film. This will lead to 2 beams

lighting the Hologram film from the same side. One

beam straight from the laser source and the other reflected

by the object. These 2 beams interfere with each other.

Thus, an interference pattern is recorded on the Hologram

film. After having developed the Hologram film, the

obtained master Hologram can be viewed by lighting the

master Hologram againwith the reference beam under the

same angle. The original object now can be seen through

the master Hologram. object

beam, is sent to the object, which is placed in front

of the Hologram film. This will lead to 2 beams

lighting the Hologram film from the same side. One

beam straight from the laser source and the other reflected

by the object. These 2 beams interfere with each other.

Thus, an interference pattern is recorded on the Hologram

film. After having developed the Hologram film, the

obtained master Hologram can be viewed by lighting the

master Hologram againwith the reference beam under the

same angle. The original object now can be seen through

the master Hologram.

The making of a reflection Hologram does not differ

very much from the making of a master Hologram. The

only substantial difference is where the light hits

the Hologram film. The making of a master Hologram

required the lighting of the film from one side. The

making of a reflection Hologram requires the lighting

of the Hologram film from both sides. So the reference

beam will light the film from the front, and the object

beam will light the film from the back side.

Now a Hologram is obtained that can be viewed best with

a halogen lightsource or in sunlight. The Hologram has

to be lighted from above under an angle of 45 degrees.

Simple instruction of master shooting

lab(Dot-matrix) and master shooting

Hologram Dot-matrix Maker is a powerful

and unique tool to design and fabricate DOVID (diffractive

optical variable image device), kinetic 2D/3D, Sterogram

and true color holograms which lead HoloMakerseriesto

be the best digital dot-matrix Hologram printing

or mastering system in the world.

D. Electronic forming

Machine(Hologram Printer)

small

Hologram electronic

forming Machine(Hologram Printer) small

Hologram electronic

forming Machine(Hologram Printer)

big

Hologram electronic

forming Machine(Hologram Printer) big

Hologram electronic

forming Machine(Hologram Printer)

Specifications of small Hologram electronic

forming Machine(Hologram Printer)tank:

1. Max electronic formed size:1200MM*400MM

2. Voltage std.:380V 50HZ

3. Power consumption:5KW

4. dimension: 800MM*800MM*1000MM

5. weight: 300KG

Specifications of Hologram

electronic forming Machine(Hologram Printer):

1. Max electronic formed size:1200MM*400MM

2. Voltage std.:380V 50HZ

3. Power consumption:2KW

4. dimension: 400MM*600MM*800MM

5. weight: 250KG

E.

Laminator(Coating Machine(Hologram Printer)) for Hologram material laminating

1.HL Serie A Film Laminator:

Usage£ň

This Machine(Hologram Printer) is suitable for Hologram material laminating,

such as PET film, pressure sensitive Hologram

metalized film, non pressure sensitive Hologram metalized

film, transparent Hologram film, transparent Hologram

card, etc..

Features£ň

1. Flat structure is used for dry oven, with track chain

for transporting material.

2. Frequency-control stepless regulation is adopted

for whole Machine(Hologram Printer) set.

3. High automation level, easy for operation and maintenance.

4. Drying oven is added behind cooling box, with multi-stage

control of temperature.

5. Two-position rotary winding table is adopted, realizing

automatic rewinding by fixed length with

2.HL Serie B Laminator:

click link to see running embosser or

right click mouse to 'save as...' to download it

Vedio1 Vedio2

Vedio3

Specifications:

Laminator Specifications:

1. Adhesive Machine(Hologram Printer) weight: 500KG

2. Adhesive Machine(Hologram Printer) L5900MM*W450MM* H1700MM

Laminator controller

Specifications:

1. Adhesive Machine(Hologram Printer) controller weight: 150KG

2. Adhesive Machine(Hologram Printer) controller dimension: L600MM*W450MM*

H950MM

|

object

beam, is sent to the object, which is placed in front

of the Hologram film. This will lead to 2 beams

lighting the Hologram film from the same side. One

beam straight from the laser source and the other reflected

by the object. These 2 beams interfere with each other.

Thus, an interference pattern is recorded on the Hologram

film. After having developed the Hologram film, the

obtained master Hologram can be viewed by lighting the

master Hologram againwith the reference beam under the

same angle. The original object now can be seen through

the master Hologram.

object

beam, is sent to the object, which is placed in front

of the Hologram film. This will lead to 2 beams

lighting the Hologram film from the same side. One

beam straight from the laser source and the other reflected

by the object. These 2 beams interfere with each other.

Thus, an interference pattern is recorded on the Hologram

film. After having developed the Hologram film, the

obtained master Hologram can be viewed by lighting the

master Hologram againwith the reference beam under the

same angle. The original object now can be seen through

the master Hologram.

small

Hologram electronic

forming Machine(Hologram Printer)

small

Hologram electronic

forming Machine(Hologram Printer) big

Hologram electronic

forming Machine(Hologram Printer)

big

Hologram electronic

forming Machine(Hologram Printer)